Laser Module

Introduction

A laser module is a precision optical device that emits a highly focused beam of light. Laser stands for Light Amplification by Stimulated Emission of Radiation. Unlike ordinary light, a laser beam is coherent, monochromatic, directional, and highly energetic. Laser modules are commonly used in engraving, cutting, measurement, scanning, communication, and scientific applications.

Types of Laser Modules

- Diode Lasers: Compact, low-power modules (1–5W) used in engraving and marking machines.

- CO2 Lasers: Gas lasers (10–150W) used for cutting wood, acrylic, and fabrics.

- Fiber Lasers: High-power, compact solid-state lasers used for metal marking.

- DPSS (Diode-Pumped Solid-State): Produces green or blue laser light for precision applications.

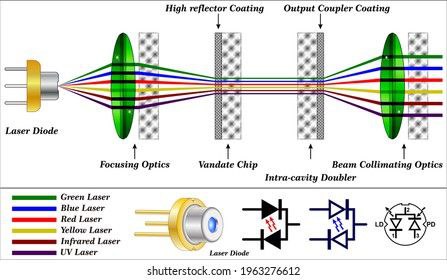

Working Principle

Laser modules operate on the principle of stimulated emission. Inside the module:

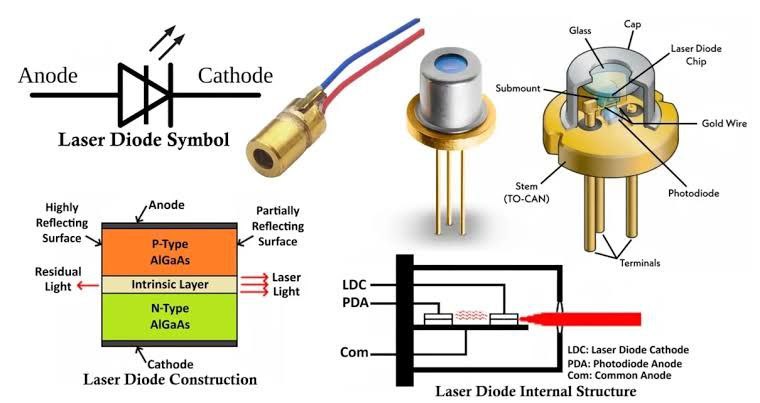

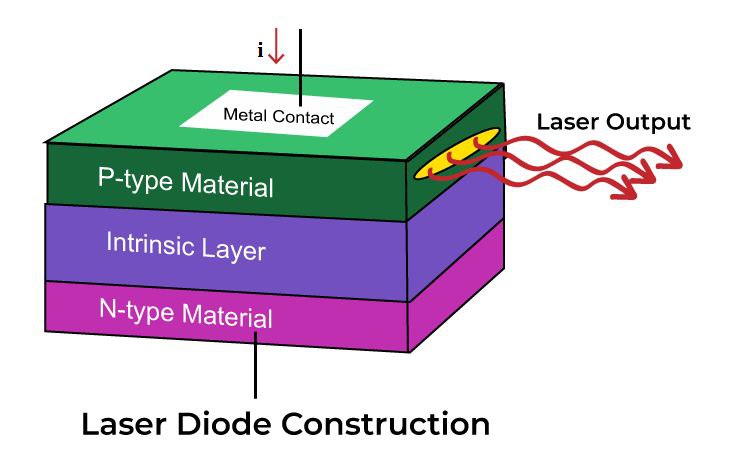

- The laser diode emits photons when electrons recombine with holes in the semiconductor material.

- Mirrors inside the cavity reflect photons, stimulating more photon emissions in phase, creating a coherent beam.

- A collimating lens shapes the beam into a narrow, focused line that can be precisely controlled.

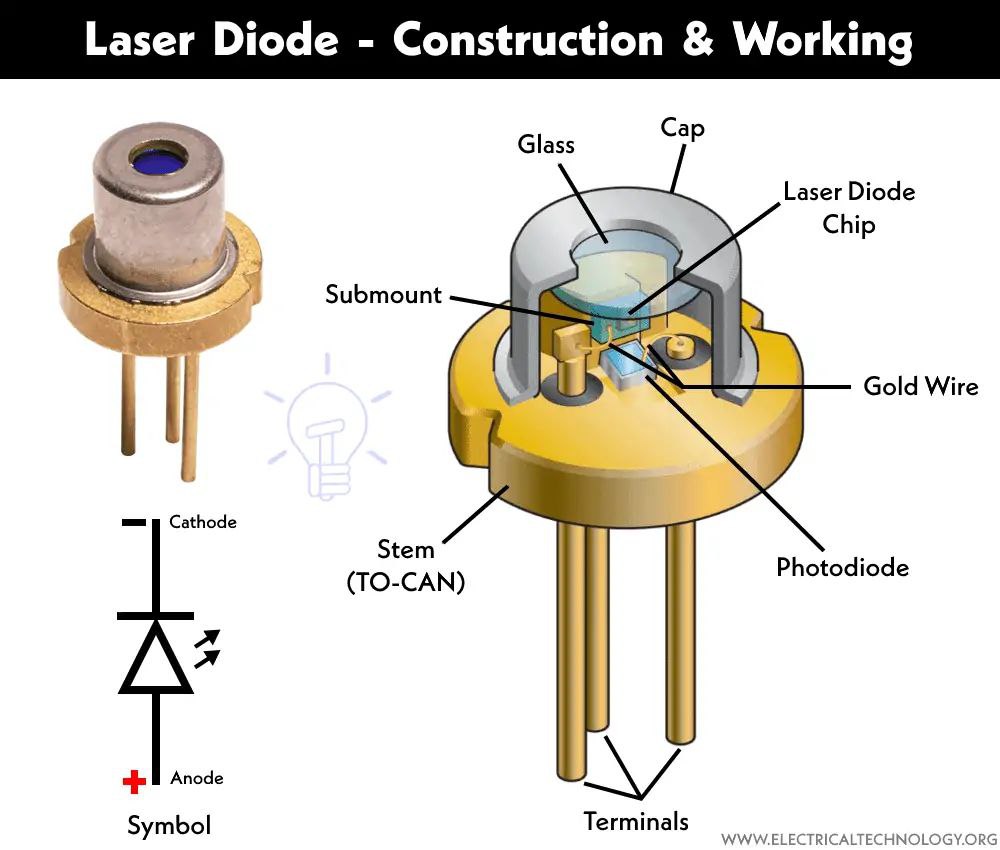

Electrical Components

- Laser Diode: Core element producing light.

- Driver Circuit: Regulates voltage/current for stable laser operation, protects against overcurrent, and allows PWM/TTL control.

- Heatsink & Cooling Fan: Dissipates heat to maintain diode efficiency and lifespan.

- Collimating Lens: Focuses the laser to a tight point.

- Protective Housing: Metal enclosure for safety and durability.

Optical Characteristics

- Wavelength: 405–450 nm for blue lasers, 520–532 nm for green, 650 nm for red.

- Beam Divergence: 0.5–2 mrad (smaller is tighter beam).

- Spot Size: Depends on lens and distance, usually 0.1–1 mm.

- Power Output: 1–5W for engraving modules; up to 150W for industrial CO2 lasers.

Applications

- Laser engraving on wood, acrylic, leather, and plastics.

- Cutting thin sheets of wood, acrylic, cardboard, or soft metals.

- Precision marking on metals and circuit boards.

- Measurement systems, optical sensors, and laser alignment tools.

- Scientific experiments, holography, and optical communication.

Advantages

- High precision and repeatability.

- Non-contact processing reduces material deformation.

- Fast operation compared to manual cutting/engraving.

- Works with various materials, from wood to metal.

- Long lifespan if properly cooled and powered.

Limitations

- Laser safety is critical — can cause eye/skin damage.

- High-power modules require good heat dissipation.

- Limited cutting depth depending on power and material.

- Material reflectivity can affect performance (especially metals for diode lasers).

Connection with MKS Board

Laser modules connect to the MKS board typically via a 12V power output and a PWM/TTL control signal. - The 12V line powers the diode and driver circuit. - The PWM signal from the MKS board controls laser intensity, allowing precise engraving patterns. Proper wiring, current limiting, and cooling are essential to avoid damage.

Safety Precautions

- Always wear laser safety goggles suitable for your laser’s wavelength.

- Never look directly at the beam or its reflection.

- Keep the module securely mounted and avoid loose wires.

- Ensure proper ventilation — fumes from engraving materials can be harmful.

- Disconnect power before adjusting lenses or wiring.

- Follow manufacturer current and voltage ratings strictly.

Maintenance Tips

- Regularly clean the collimating lens to avoid beam distortion.

- Check cooling fans for dust and proper operation.

- Verify driver circuit connections for stability.

- Monitor diode temperature; avoid running continuously at max power without proper cooling.